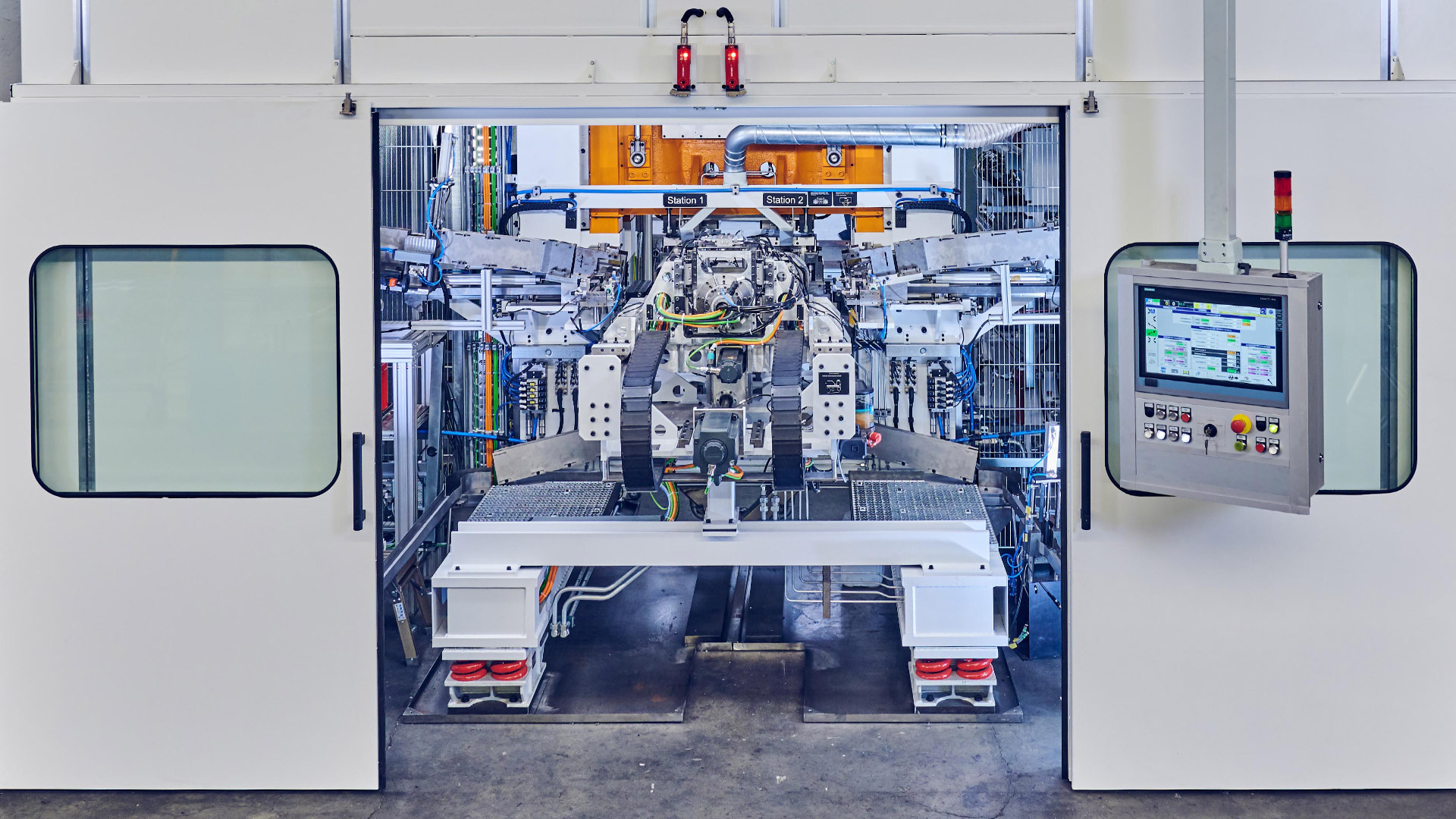

RASTER® Technology HLKK 1000

The new dimension for manufacturing ball bearing cages

Ball bearing cages are an important part of every CV joint. They are essential in automotive engineering because they ensure smooth torque transfer to the road in motor vehicles of all kinds.

Intelligent machine concept

The solid design provides a stable foundation for all cutting operations.

Massive press frame prevents rebounding

Gray cast iron for improved damping

High rigidity thanks to tie anchors

Robust, long-lived design with high availability

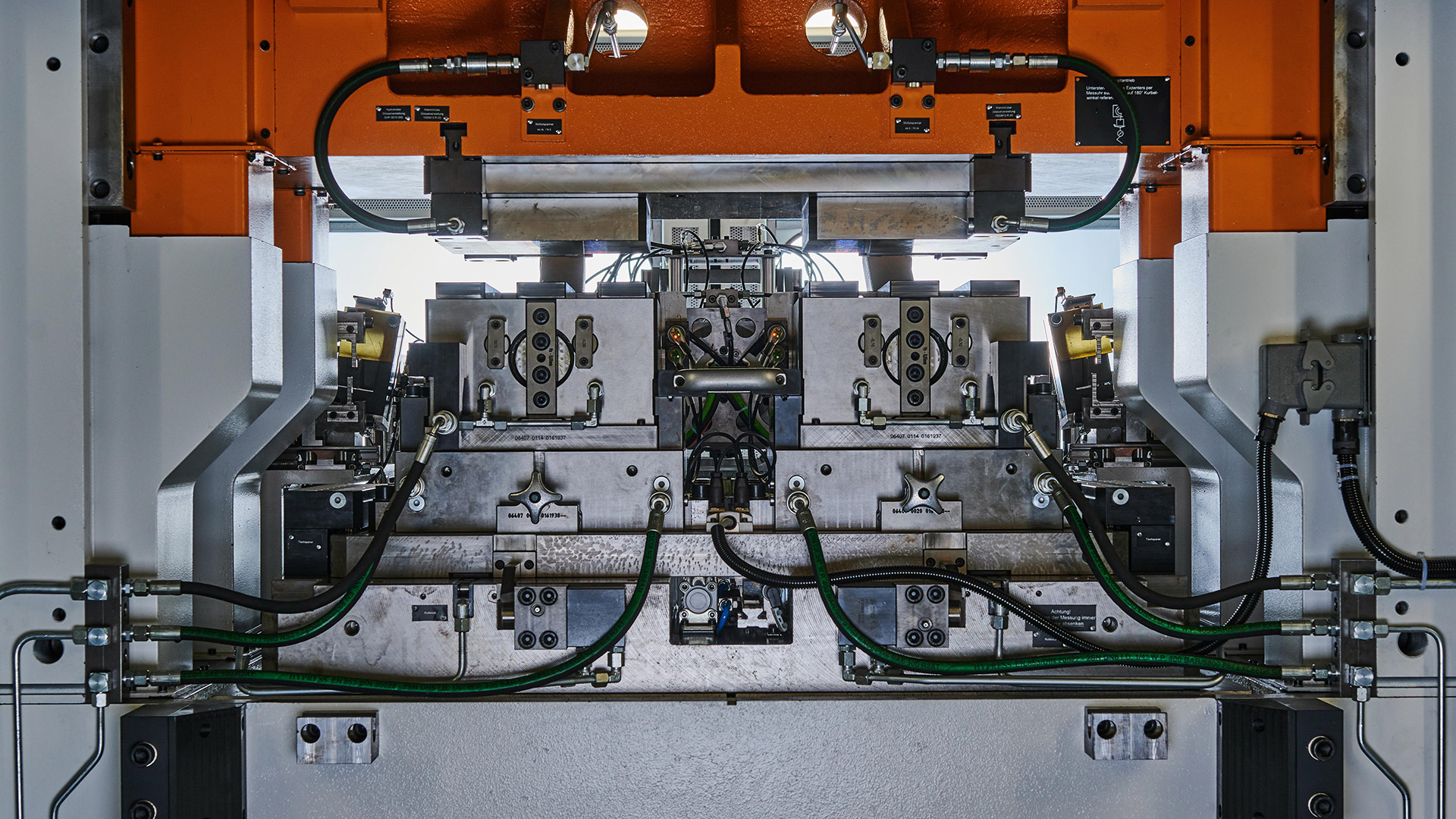

Controlled force

The highly dynamic AC servomotor ensures outstanding punching quality with high cutting speeds.

The motor acts directly on the eccentric shaft via a low-play planetary gear

High speed at the bottom dead center for high surface quality

Low speed at the top dead center for precise indexing movements

Fast and efficient

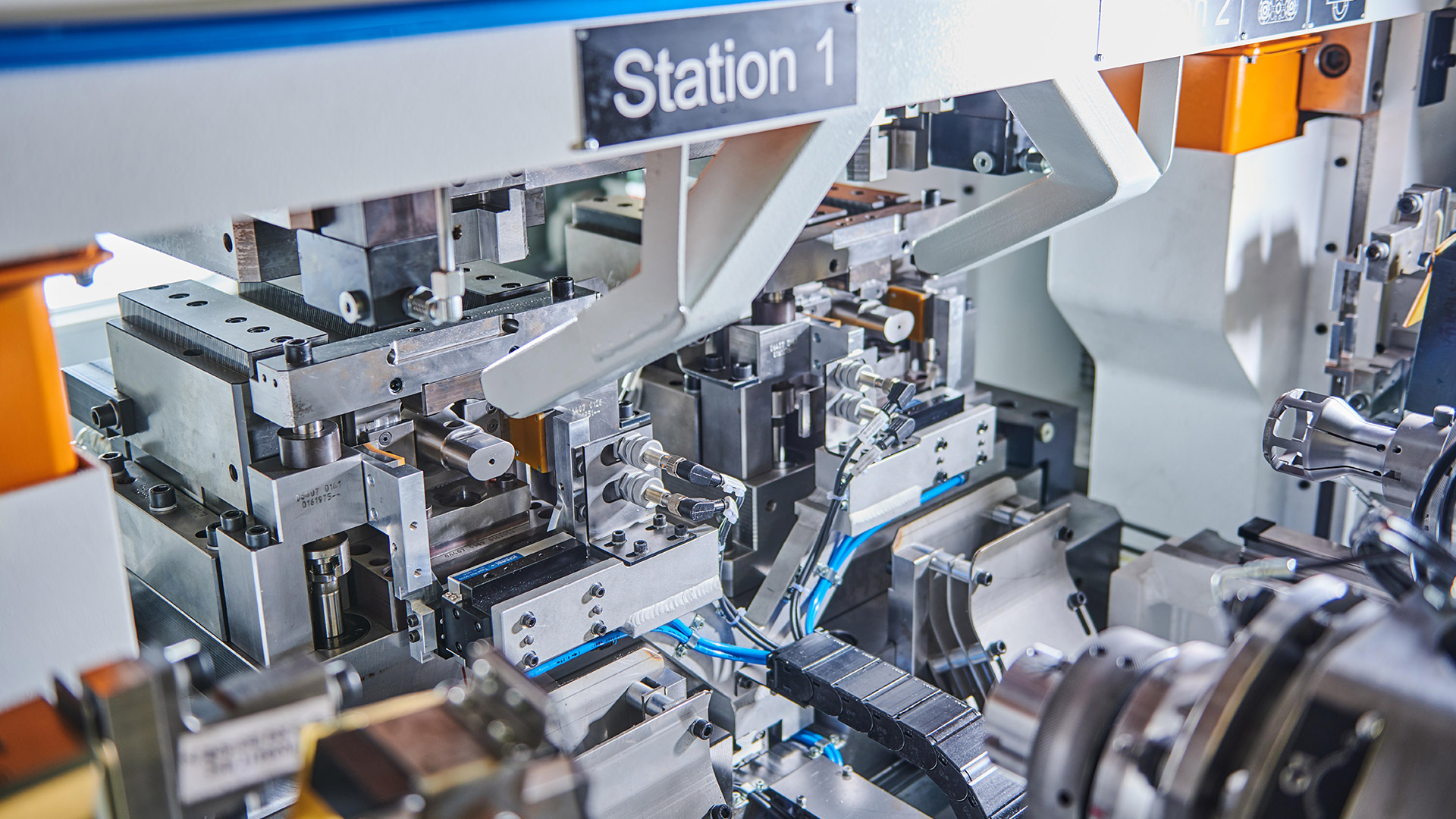

The HLKK 1000 is designed for both large quantities and fast-changing small series.

Fast, operator-friendly adjustment due to just few parameters

Extremely short changeover times of 0.5 instead of 8 hours

Freely programmable part feeding system

Flexible ball bearing cage dimensions with:

- Freely programmable number of windows

- Inner diameter 35–70 mm

- Window length 10–50 mm

- Height 20–80 mm

- Wall thickness 0.5–10 mm

- Two independently programmable punching stations

All advantages on your side

Higher output – thanks to up to 300 punching operations per minute

Higher surface quality – thanks to fast cutting speed

Higher flexibility – thanks to wide punching range

Higher efficiency – thanks to extremely short changeover times

Higher reliability – thanks to outstanding machine concept

Contact

Please contact us with your questions, comments, etc.

We look forward to your e-mail.